| Item | Model | Ampeepet 1000 | Ampeepet 5000 |

|---|---|---|---|

| Max. Product Capacity | ml | 2000 | 5000 |

| Min. Product Capacity | ml | 60 | 100 |

| Max. Neck Diameter | ml | 30 | 120 |

| Max. Product Height | mm | 340 | 340 |

| Production Capacity | Piece/Hr | 700 to 900 | 250 to 450 |

| Max. Blow Height | mm | 350 | 350 |

| Cavity | Nos. | 2 | 1 or 2 |

| Working Pressure | Bar(kg.) | 8 | 8 |

| Blowing Pressure | Bar(kg.) | 20 to 25 | 15 to 20 |

| Heater Power Connected | KW | 12 | 14 |

| Clamping Strock | mm | 140/150 | 240/250 |

| Mold Platen Size | mm | 440x340x35 | 440x340x35 |

| Tie Bar Distance | mm | 330 | 330 |

| Max Mold Thickness | mm | 140 | 225 |

| Min. Mold Thickness | mm | 50 | 140 |

| Clamping Force | Ton | 8 | 15 |

| Cavity Center Distance | mm | 150 | - |

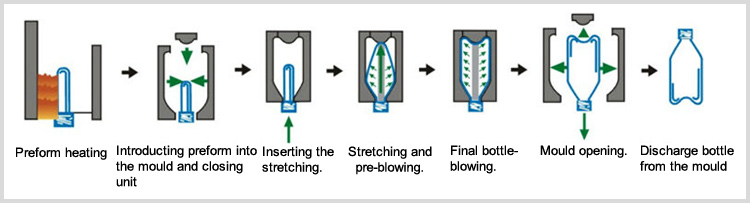

AMPEEPET a manual two-stage re-heat hi-directional pet stretch blow moulding machine is the latest developed product from our factory. It is product Pet hi-oriented containers in two stages; having the advantages of being compact in size with low power consumption, low investment cost of sample structure and convenient to maintain. The machine can blow various geometric plastic containers that can be used in packing for goods.

Mineral and Distilled Water, Carbonated Drink, Food and Candy, Sauce and Juice, Edible Oil, Detergent, Pharmacy, Cosmetric, Liquor.